Angle grinder for fresh and frozen meat blocks with sophisticated technology

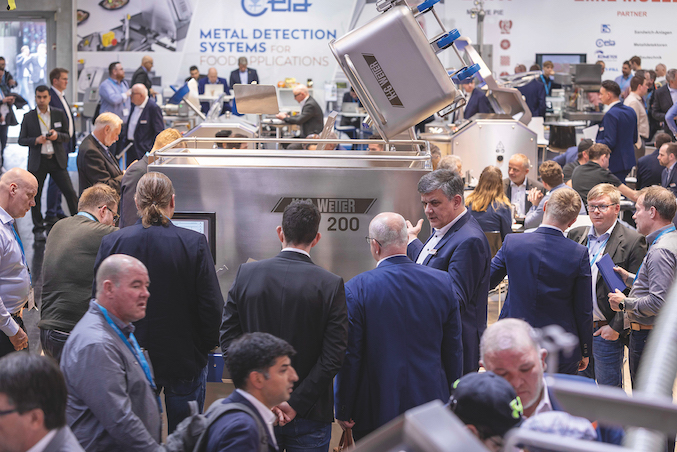

K+G Wetter spent four well-attended days at the Anuga FoodTec in Cologne. “We are extremely satisfied with the Anuga. Our salespeople and technicians were in conversation from morning to night – with long-standing customers from all over the world, but also with companies that are not yet working with our machines,” reports K+G Wetter managing director Andreas Wetter.

The new Winkelwolf WW 200 was always surrounded by interested trade fair visitors - and scored points with food experts with its useful machine technology. “We always listen carefully to our customers when they talk about working with the machines. From this, our team then comes up with technology that really proves its worth in practice,” says Volker Schlosser, International Sales Manager at K+G Wetter. The special thing about the powerful angle grinder WW 200: In addition to fresh products, it also processes blocks of frozen meat without pre-shredding. This makes it unrivaled in its flexibility and perfect for businesses that work with a mix of fresh and frozen meat.

This is made possible with carefully thought-out technology: The 500 liter hopper of the WW 200 has a special, asymmetrical shape - this means that meat and other ingredients reach the feed screw evenly after loading. The special frozen meat feed screw with cutting edge shreds the blocks during transport to the meat screw: the meat is cut precisely from the block and is not crushed. The temperature increase is also minimal due to the low product stress. This ensures a clear cut image of the finished product.

Thanks to well-thought-out Hygienic Secure features, the WW 200 can be cleaned in a time-saving and perfectly hygienic manner, as is standard for all K+G Wetter machines. The expertly hand-polished stainless steel surfaces are easy to keep clean; the slanted arrangement means that cleaning water runs off without puddles forming. The feeder and meat auger can be removed and re-inserted in just a few steps without tools. This also makes hygienically safe cleaning easier. The single-stage folding step makes the WW 200's hopper accessible quickly and safely while requiring minimal space - cleverly solved for both handling and hygiene.

The rinsing chamber prevents a typical hygiene risk caused by hidden contamination inside the machine behind the seals of the drive shaft and feed screw. Daily cleaning is carried out from the outside by simply holding the usual cleaning lances or spray nozzles to the easily accessible flushing accesses. The seals that come into contact with the product are cleaned on both sides and do not provide a breeding ground for microorganisms. Thanks to this ingenious technology, the additional effort required for cleaning is negligibly low with maximum effectiveness.

The options for loading the WW 200 are very flexible. Whether mast loading or hydraulic loading using a meat cart: How and from which side the raw materials are loaded into the angle grinder can be individually adapted depending on the space situation and the customer's work processes. A big plus thanks to a machine that is optimally adapted to the respective production.

The optional large touch panel provides operators with lots of practical information, clearly presented in graphics and text: for example, about possible cutting set configurations or optimal machine settings for different applications. This makes operation easy and safe and ensures the best product quality.