IFFA, Impressions 2022

It seems that the IFFA survived the Corona period well. The aisles are well filled with trade visitors and the The mood among the exhibitors is also positive. The fact that no Russian companies are exhibiting didn't strike me negatively. But what struck me was that there are not only good machines from Germany, but also that numerous large companies from all over Europe, including Eastern European countries and Turkey, are exhibiting at the IFFA. Especially in the area of innovation, our European neighbors are at least on a par with us.

In the field of conventional machines, such as cutters, mincers, mixers, filling machines and smokers, German mechanical engineering has faced really strong competition, such as the company PSS from Slovakia, the company Nowicki from Poland and numerous other companies.

Still, that's my impression "it almost plays into the hands of the machine manufacturers" that there are fewer and fewer employees in the meat industry. Numerous innovations deal with automation technology that requires fewer and fewer employees. What has remained at IFFA is the focus on industrial companies, on large-scale applications.

This is how the company shows us in the following video Pintro from Belgiumhow to use robotics to make a wide variety of skewers quickly and effectively. Bratwurst snails, which has always been a very individual and complex article, is now almost completely independent rotated by the machine, skewered and placed in MAP trays:

| For Tipper Tie shows how even heavy and long sausages up to 1,7 m and 10 kg each can be hung on smoking trolleys at an almost “breathtaking speed” without human intervention: |

|

|

The Italy based company INOX MECCANICA has, how could it be otherwise, on an effective ham production specialized. Meat products, whether raw or cooked, in a wide variety of shapes and dimensions, with and without a net, are brought into really even shapes that can be sliced. Other manufacturers, such as Bettcher, are making small improvements to their electric circular knives. Energy-saving engines, maintenance-free drive trains, delicate spare parts supply and ingenious weight distribution for better handling are some of the innovations. At the GEA company, known to be a leader in the industry, I was able to observe sophisticated slicer systems with automatic feeding of the piece goods and improved cutting technology. In the ideal case, the pieces to be cut (somewhat product-dependent, of course) should have less than 2 cm of end pieces.

The Dutch Foodmate company is a specialist in chicken cutting. At the IFFA she set up a cutting line for boning chicken breasts. Not only are the chicken breast fillets released fully automatically, but first the skin is removed, then the fork bone on the upper breast is removed (in order to achieve the best possible yield) and, to top it off, the inner breast fillet is separated from the normal chicken breast fillet. From my point of view, this really is a fine art of automation technology.

| The Seydelmann company As has been the case for years, it occupies a lot of space in Hall 8. A production line for the production of boiled sausages catches the eye and can almost be described as gigantic. The line should produce between 4-4,5 t/h sausage meat. The main focus on the line is the buffering of intermediate items to further increase efficiency. In a mixer with a capacity of 2,8 t, the sausage meat can be cooled down using CO2 during the mixing process and a vacuum can also be drawn. The sausage meat is then filled into a buffer tank that can hold the entire mixer. The sausage meat is then pumped fully automatically from this buffer tank to the continuous cutter: |

|

Furthermore, the company Seydelmann recently a mixer in the portfolio, in which the cutter carriage is simply driven into the machine and the cutter carriage is then sealed airtight using a vacuum. The complete cutter wagon then rotates around its own axis several times so that the ingredients in the cutter wagon are mixed together. The advantage lies in the reduced handling of the mixing process. Whether the whole thing can also be realized with used and slightly warped cutter wagons, nobody could answer me: |

|

|

The filling specialists like that Handtmann and Vemag both have reserved a lot of exhibition space. Both companies focus on complete filling lines that leave almost nothing to be desired in the area of casing-free filling of meat products. No matter what shape, what length, whether balls, paddies or bars, everything can nowadays be filled highly efficiently using such filling machines. In the company GEA I have seen a cutter that was already modified for vegan or vegetarian food. In addition to the vacuum device, this cutter also has the automatic supply of nitrogen and cooking oil. In addition, slight modifications were made to the cutter knives.

For Espera has a camera system presented, which checks both the labels of the prepackages and the complete pack at the end of the conveyor for proper condition. Rejected packs are automatically ejected. These camera systems are finding their way more and more into production lines. For example, the Weber company showed a laser scanner that captures the dimensions of unequal = native meat products at a 360° angle. This is intended to achieve the specified pack weights much more evenly.

| The way food is Graselli company, known for its vertical and horizontal cutting systems for fresh meat, uses such scanners in order to be able to record the dimensions of the native fresh meat items and thus better control the cutting thickness of the individual slices. There are both laser scanners, LED scanners as well XRAY scanner (X-rays). The latter are mainly used in quality assurance to identify all possible foreign substances in packs. Such devices are able to find out all substances that do not contain protein: |

|

Another trend, which was also confirmed to me by various exhibitors, is that that the portfolio of many companies is constantly growing. The enlargement of the offer is often generated by that simply bought up companies that match your own previous articles. So the company TVI was bought by Multivac. The Icelandic company Marel expanded its portfolio by acquiring the companies Maja and Treif. This has progressed so far that the latter two companies no longer appear on the relevant machines. Too bad.

Multivac offers a tubular bag machine from its own development and thus further expands its product range. In the area of traysealers, Multivac competes with Sealpac's own machines. This, in turn, the industry leader in the traysealer sector, has also been trying its hand at conventional thermoforming packaging machines for a number of years. Or look at the Bizerba company, which originally grew up with slicing machines and scales for the butcher's trade. In addition to the well-known products, it also offers chamber vacuum machines, quality assurance devices with Xray technology, filling systems and logistics systems (conveyor belt technology).

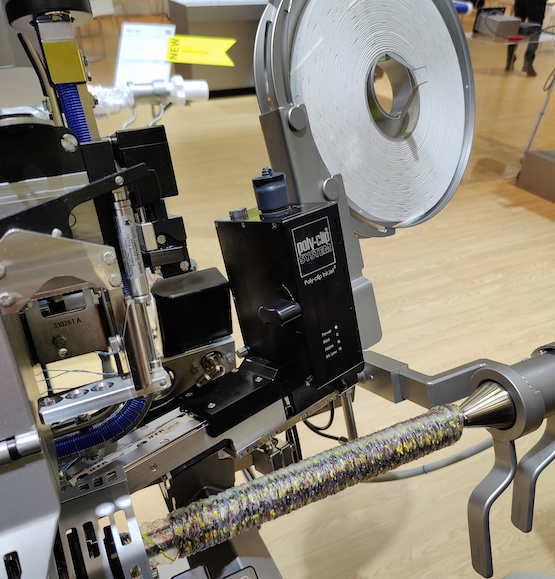

| At company Polyclip numerous machine types have been optimized in terms of power consumption. A labeling system was implemented for 2 machine types, the PDCA clip machines, which (attached to the clip) can also display all ingredients via a QR code in addition to the best-before date. This means that you can save yourself the additional label on the finished sausages. However, this requires that I have a QR code scanner = smartphone available: |

|

|

|

|

With kind regards,

Jürgen Huber

(Author at fleischbranche.de / management consultant for the meat industry)