New business area at Handtmann: original blade sets

Everything from a single source and therefore optimally coordinated: With its new, original Premium Handtmann blade set (PH), Handtmann now offers the optimal synchronization of the latest vacuum filling technology, inline grinder and separating technology with a coordinated blade set and the option of smart blade set management. The technology can be used universally in all production processes for meat and sausage products, vegetarian and vegan products or cheese and vegetable products. When changing products, it is not necessary to exchange conveyor system parts in the vacuum filler, since the standard conveyor system is used for all products, regardless of the cut size of the end perforated disc. This enables the processing of very cold products, a high filling capacity for small-grain end products or new production options for raw sausage, fresh sausage and other coarse-grain products. Separating and straining applications for potato, vegetable and fruit products are also possible.

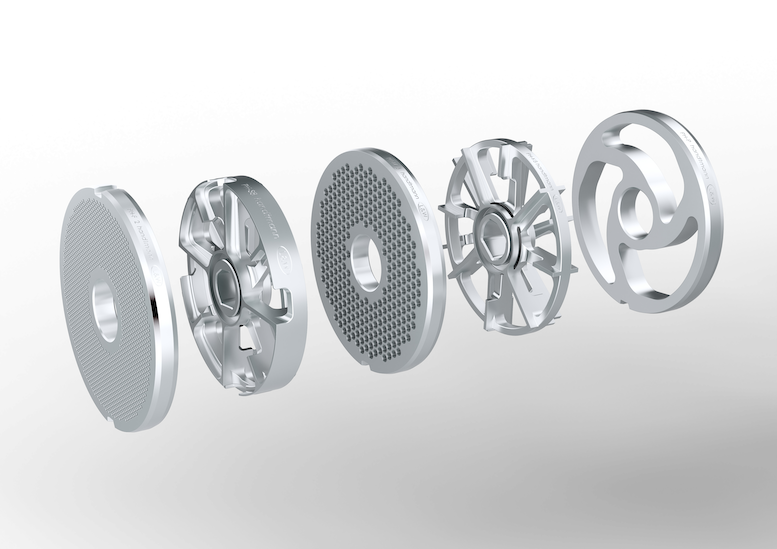

The original PH cutting set ensures that the raw material is cut gently, precisely and energy-efficiently in all applications, with minimal product heating. The cause lies in the optimal blade set geometry, which ensures that the material flows through the perforated disc in a manner that is gentle on the product. This causes a significant reduction in pressure inside the grinder housing, resulting in a perfect cut with an even grain size. The reduction in frictional resistance brings additional product protection and hygiene advantages. The optimum flow of material into the Premium Handtmann blade set is achieved through the perfected geometry of the spur. The asymmetrical blade arrangement on the premium knives then ensures an even cutting process. The mixing effect when flowing through the material is even more effective thanks to the recess on the back of every second blade. The aerodynamic perfection of the channel on the knife arms also causes cartilage and tendons to flow away and be carried out in a targeted manner. The support cross is designed in such a way that the support arms do not cover any holes on the end perforated disc. In this way, the material flows unhindered through the entire open area and smearing points and deposits are avoided. The new cutting set is available for the inline grinder types GD 451 and GD 93-3 in perforated discs with a bore diameter of 1,0 mm to 13 mm, knives in the 6- and 8-arm design as well as 8-arm separating knives.

Optionally, the PH blade set can be equipped with a label that enables clear assignment to the respective vacuum filling machine and the respective product. In connection with the HCU software solution, smart cutting set management is possible with complete documentation, evaluation and management of the respective cutting set. The documented performance parameters and flow rates provide full transparency of the cutting process and consequently process and product safety along with minimization of disruptions. In the case of the perforated discs, the cross support and the knives, the direction of installation is also specified by a mechanical installation coding, so that the parts can only be inserted in the correct direction. This prevents incorrect installation with the corresponding consequential damage to the parts and the contents. A flawless production process with constant results is thus ensured.

|

|

| VF 828 S with inline grinder GD 451 with volume separator | 5-piece premium Handtmann blade set |

About Handtmann filling and portioning systems (F&P)

The Handtmann F&P division is part of the owner-managed Handtmann group of companies based in Biberach in southern Germany. It is a leading manufacturer of process technology for processing food and offers modular and cross-process line solutions from product preparation to packaging solutions. The offer is flanked by in-house developed, process-supporting digital solutions. At the same time, investments are made in sustainable concepts for food innovation. This also includes the state-of-the-art technology and customer centers at the company headquarters. The Handtmann Group employs around 4.100 people worldwide, including around 1.500 at F&P. With numerous subsidiaries and sales and service partners, the company is represented globally in over 100 countries and is also networked across the board through strategic partnerships. More information at: